Oil Service Classifications and Oil Grades - Select Synthetics - AMSOIL Authorized Dealer

Main menu:

- Home Page

-

Products

-

AMSOIL Products

- Shop by Product

- Shop by Equipment

- Shop by Category

-

Product Lookup Guides

- Product Lookup Guides - Home

- Filter Lookup Guides

- Auto & Light Truck Lookup Guide

- Motorcycle & Dirt Bike Lookup Guide

- Harley-Davidson Products Guide

- All-Terrain Vehicle Lookup Guide

- Utility Terrain Vehicle Lookup Guide

- Snowmobile Lookup Guide

- Marine Outboard Lookup Guide

- Personal Watercraft Lookup Guide

- Small Engine Lookup Guide

- Free Product Catalog

- AMSOIL - The Blog

- AMSOIL YouTube Videos

- AMSOIL Performance Tests

- The AMSOIL Newsstand

- AMSOIL Testimonials

- AMSOIL Guarantee

- Safety Data Sheets

- Oil Analysis Services

- Shipping & Product Return

- Safe & Secure Shopping

-

AMSOIL Products

- About AMSOIL

-

Oil Basics

- What Is Motor Oil?

- What Is Oil Viscosity?

- What Does Motor Oil Do?

- Why Does Oil Need To Be Changed?

- How Often Should I Change My Oil?

- When Should I Do My 1st Oil Change?

- Can I Mix Different Oils?

- Lubrication Regimes

- Newtonian vs. Non-Newtonian

- Base Oil Groups

- Motor Oil Specifications

- Service Classifications & Grades

- Oil Evaluation Tests

- Oil Filtration

- What is Oil Analysis?

- Why Synthetics?

- Buy Wholesale

- FAQs

- Contact Us

Oil Basics

Service Classifications & Grades

Motor Oil Service Classifications and Viscosity Grades

The “API” and the “SAE”

Motor oil quality has changed dramatically in the past 50 years, and new demands on lubricants in modern engine designs call for oils that meet stringent requirements. Variations in oil’s ability to meet the requirements determine which service classification rating and viscosity grade it receives.

Service classifications are determined by the American Petroleum Institute (API), while oil viscosity grades are determined by the Society of Automotive Engineers (SAE). These two organizations have set industry standards for motor oils for more than 80 years.

Motor Oil is classified by two systems. One system determines the oil's viscosity rating (the SAE grade), and the other (the API classification) determines its performance level and appropriate applications. Both of these designations are displayed on the API Service Classification Symbol, also known as the API “Donut”.

The API Service Symbol "Donut" is divided into three parts:

3- The bottom half tells whether the oil has demonstrated energy-conserving properties in a standard test in comparison to a reference oil, or if an oil meets CI-4 PLUS requirements.

API's Engine Oil Licensing and Certification System (EOLCS)

“API's Engine Oil Licensing and Certification System (EOLCS) is a voluntary licensing and certification program that authorizes engine oil marketers who meet specified requirements to use the API Engine Oil Quality Marks—the API Service Symbol "Donut" and Certification Mark "Starburst."

This program is a cooperative effort between the oil industry and vehicle and engine manufacturers Ford, General Motors, and Chrysler; the Japan Automobile Manufacturers Association; and the Engine Manufacturers Association.

Performance requirements, test methods, and limits are cooperatively established by vehicle and engine manufacturers, technical societies like the Society of Automotive Engineers (SAE) and the American Society for Testing and Materials (ASTM) and industry associations like the American Chemistry Council and API.” (www.api.org)

In other words, the Licensee pays a Licensing Fee to API which then entitles them to use the coveted API Service Symbol “Donut” on the back label of their Motor Oil as well as the API Certification Mark, also known as the “Starburst” on the front label. The API Certification Mark "Starburst" is designed to identify engine oils recommended for a specific application (such as gasoline service).

An API license indicates that a specific motor oil formulation has passed the minimum performance standards as defined by a series of laboratory bench, physical, chemical and engine tests.

These tests and minimum performance standards are determined by the API Lubricants Committee to address specific areas such as engine wear, deposits, fuel economy and emissions. The committee is comprised of representatives from automobile, oil and additive companies.

Additive companies develop licensed formulas that they offer to oil companies to re-license. It is inexpensive to re-license one of these formulas, and the majority of oil companies choose to do this to avoid the costs associated with testing their own formulas. This lowers the value of such engine oils because the same chemistry is being sold under many brand names.

While the Licensed Motor Oil must meet the established minimum for performance under a specified API Category, other than this minimum performance requirement, there is no differentiation in any product that exceeds the minimum.

In other words, there are many cheap, low quality, inexpensive conventional oils that meet the API minimum performance standards and display the “donut” and “starburst” quality marks on their packaging. But does this mean that their performance level is on par with high quality 100% full synthetic oils (e.g. AMSOIL)? Absolutely not! They’re in a totally different performance category. Unfortunately, API doesn't make a distinction between performance levels.

Additionally, according to a recent API survey of more than 1,800 oil samples purchased from bulk dispenser tanks in quick lube shops across the U.S., nearly 20% (one out of five) were mislabelled and failed to meet API standards. Either the viscosity was incorrect or the additive package failed to meet the performance requirements.

API and AMSOIL

The lubricant formulas from AMSOIL, who produced the world’s first API-qualified synthetic motor oil in 1972, are unique and proprietary. How does the company ensure that its products meet or exceed the minimum specifications of the tests required for API licensing?

First, AMSOIL works closely with major additive companies to select the top-performing, and usually most expensive, passenger car and heavy-duty diesel motor oil additives. These additives have already passed all of the API licensing requirements in a petroleum- or synthetic-based formulation.

Then, it works with the additive company to maximize the amount of additive used and to boost the additive package in selected performance areas to achieve an optimum performing additive package for the intended application.

This is unlike many other oil companies that, because additives are expensive, use the minimum amount of the least expensive additives required to meet the minimum API requirements.

It then uses a combination of synthetic base stocks with known performance characteristics as replacements for the petroleum base stocks to optimize performance in areas of lubricity, volatility, viscosity index, oxidation and nitration resistance, pour point, flash point, deposit control, soot handling, emissions and many other areas as well.

It also uses a high-quality Viscosity Index Improver (VII) with outstanding viscosity and cleanliness properties. This replaces the inexpensive, low-quality VII used in standard API-licensed petroleum formulas.

AMSOIL does laboratory bench tests and runs field tests to verify the superiority of the synthetic formula. It continues to monitor the performance of the oil through close scrutiny of tens of thousands of oil analysis tests per year across a wide variety of vehicles all around North America and the world.

AMSOIL has been collecting used synthetic oil samples from passenger cars since 1982. No other oil company has such a vast database of the performance of synthetic lubricants over extended drain intervals.

Our lubricants and formulations (both API-licensed and non-API-licensed) outperform lower quality API-licensed oils because they are engineered for top performance from the very beginning. They far exceed the API minimum requirements.

In addition, the federally mandated Magnuson-Moss Act states that a manufacturer may not require the use of a specific brand of aftermarket product (including motor oil) unless it’s provided free of charge.

The SAE Grading System

In 1911 the Society of Automotive Engineers (SAE) created a numerical code graduated system (the SAE J300 standard) to classify motor oil according to their viscosity characteristics.

Before the SAE came up with the J300 standard to classify oils by their viscosity, in simple terms that the average person could understand, there was no simple way to tell how oil would behave in a hot engine.

As a number of shortcomings were discovered the Standard was amended numerous times over the years. For instance, SAE "W" (winter) grades were added in 1952 as it became apparent that engines could not be started in very cold weather.

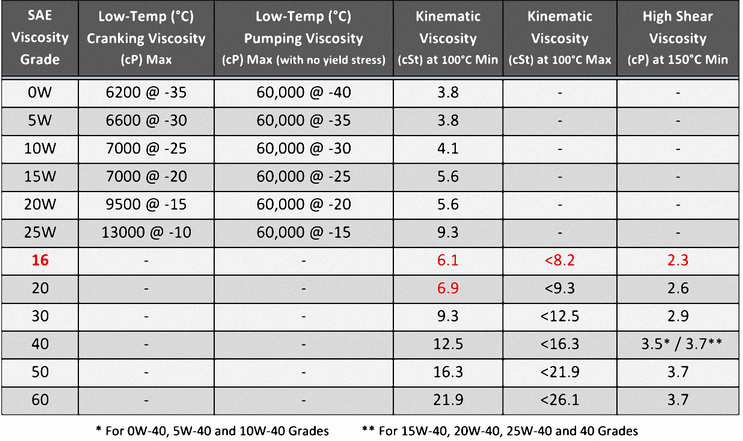

The SAE developed this system based on viscosity measures taken from a variety of tests. This resulted in 11 distinct motor oil viscosity classifications: 6 low-temperature grades (0W, 5W, 10W, 15W, 20W, and 25W) and 5 high-temperature grades (SAE 20, 30, 40, 50, and 60).

On April 2, 2013, a revision to the “SAE J300: Engine Oil Viscosity Classification” was published adding a new high-temperature viscosity grade (SAE 16) to the previous January 2009 SAE J300 table. The J300 revision was requested by a consortium of passenger car OEMs to provide a viscosity grade lower than SAE 20 in order to meet increasingly stringent fuel economy requirements.

The new grade will be specified in the future by OEMs for cars specifically designed to use new low-viscosity oils. It is not deemed to be suitable for use with older engines or newer vehicles not designed for such low-viscosity oils. Increasingly lower oil viscosity grades could be defined in the future.

Besides adding the SAE 16 grade, the new revision also revised the minimum viscosity range of SAE 20.

In the past, an SAE 20 oil grade’s viscosity range, measured at 100°C, was from 5.6 cSt to 9.3 cSt, which was a much broader range than that of SAE 30, 40, 50, or 60 grades. Additionally, the lower part of the old SAE 20 range was not being utilized. Therefore, the minimum kinematic viscosity was increased from 5.6 cSt to 6.9 cSt to bring the range of SAE 20 in line with that of the higher-viscosity grades.

These grades designate the specific ranges that the particular oil falls into. SAE 20 and SAE 20W are two completely separate classifications. The "W" or “winter” rating indicates that the grade is suitable for use in cold temperatures.

The classifications increase numerically; the lower the number, the lower the temperature at which the oil can be used for safe and effective protection. The higher numbers reflect better protection for high heat and high load situations.

Single grade oils have a limited range of protection and, therefore, a limited number of uses. With today's well-refined, high viscosity index oils, however, an SAE 20 oil usually will meet the viscosity requirements of SAE 20W and vice versa. Those that do are classified SAE 20W-20. This multi-grade or multi-viscosity ability increases oil's usefulness, because it meets the requirements of two or more classifications.

Here are some examples of multi-viscosity oils: SAE 0W-20, 5W-30, 10W-40, and 20W-50. The number with the "W" designates the oil's properties at low temperatures, while the second number characterizes its properties at high temperatures.

For instance, a multi-viscosity 5W-30 meets the 5W criteria when cold and the 30 criteria once hot. SAE 5W-30 is widely used because under all but extremely hot or cold conditions, it is light enough for easy engine cranking at low temperatures and heavy enough to protect at high temperatures.

The API Classification System

The American Petroleum Institute (API) developed a classification system to identify oils formulated to meet the operating requirements of various engines. The API system has two general categories: “S” categories and “C” categories.

“S” categories

The “S” (Service / Spark ignition) classifications are for oils designed for gasoline-engine service (cars, vans, and light trucks with gasoline-engines).

When oil passes a series of tests in specific engines (API Sequence tests), it can be sold bearing the applicable API Service or “S” classification. The classifications progress alphabetically as the level of lubricant performance increases. Each classification replaces those before it.

Oils meeting the latest API classification, API SN, may be used in any engine, including older engines where earlier category oils were recommended, unless the engine manufacturer specifies a "non detergent" oil. (SA and SB are non-detergent oils and are not recommended for use unless specified.)

Resource Conserving API SN Service Category oils, introduced in October 2010, include the performance properties of each earlier category.

They are designed to provide improved high temperature deposit protection for pistons and turbochargers, improved oxidation resistance and deposit protection, more stringent sludge control, improved fuel economy, emission control system compatibility, seal compatibility, and protection of engines operating on ethanol-containing fuels up to E85.

Not everyone is in agreement with backwards compatibility, and in addition, there are special situations, such as "performance" engines or fully race built engines, where the engine protection requirements are above and beyond API/ILSAC requirements. Because of this, there are specialty oils out in the market place with higher than API allowed phosphorus levels (such as AMSOIL’s Z-Rod oils and Racing oils).

All the current gasoline categories have placed limitations on the phosphorus content for certain SAE viscosity grades due to the chemical poisoning that phosphorus has on catalytic converters. Phosphorus is a key anti-wear component in motor oil and is usually found in motor oil in the form of zinc dithiophosphate (ZDDP).

Each new API category has placed successively lower phosphorus and zinc limits, and thus has created a controversial issue of obsolescent oils needed for older engines, especially engines with sliding (flat/cleave) tappets. Most engines built before 1985 have the flat/cleave bearing style systems, which are sensitive to reducing zinc and phosphorus.

SL (for 2004 and older gasoline-engines), SM (for 2010 and older gasoline-engines) and SN (for modern gasoline-engines) are the currently recognized API classes; previous classifications are obsolete.

“C” categories

The “C” (Commercial / Compression Ignition) classifications are for oils designed for diesel-engine commercial service (heavy-duty trucks and other vehicles with diesel-engines). They include CA, CB, CC, CD, CD-II, CE, CF, CF-2, CF-4, CG-4, CH-4, CI-4, CI-4 PLUS and CJ-4.

Not all C classifications supersede one another. These classification systems aim to help motorists choose the right oil for their applications. The choice depends on the engine, the outdoor temperature and the type of driving the engine must withstand.

The currently recognized classifications are CH-4, CI-4, and CJ-4. In addition, API created a separated CI-4 PLUS designation in conjunction with CJ-4 and CI-4 for oils that meet certain extra requirements, and this marking is located in the lower portion of the API Service Symbol "Donut".

CH-4 oils, introduced in 1998, are for high-speed, four-stroke engines designed to meet 1998 exhaust emission standards. CH-4 oils are specifically compounded for use with diesel fuels ranging in sulfur content up to 0.5% weight. They can be used in place of CD, CE, CF-4, and CG-4 oils.

CI-4 oils, introduced in 2002, are for high-speed, four-stroke engines designed to meet 2004 exhaust emission standards implemented in 2002. CI-4 oils are formulated to sustain engine durability where exhaust gas recirculation (EGR) is used and are intended for use with diesel fuels ranging in sulfur content up to 0.5% weight. They can be used in place of CD, CE, CF-4, CG-4, and CH-4 oils. Some CI-4 oils may also qualify for the CI-4 PLUS designation.

CJ-4 oils, current, are for high-speed four-stroke cycle diesel engines designed to meet 2010 model year on-highway and Tier 4 non-road exhaust emission standards as well as for previous model year diesel engines.

These oils are formulated for use in all applications with diesel fuels ranging in sulfur content up to 500 ppm (0.05% by weight). However, the use of these oils with greater than 15 ppm (0.0015% by weight) sulfur fuel may impact exhaust after-treatment system durability and/or drain interval.

CJ-4 oils are especially effective at sustaining emission control system durability where particulate filters and other advanced after-treatment systems are used. Optimum protection is provided for control of catalyst poisoning, particulate filter blocking, engine wear, piston deposits, low- and high-temperature stability, soot handling properties, oxidative thickening, foaming, and viscosity loss due to shear.

API CJ-4 oils exceed the performance criteria of API CI-4 with CI 4 PLUS, CI-4, CH-4, CG-4 and CF-4 and can effectively lubricate engines calling for those API Service Categories. When using CJ-4 oil with higher than 15 ppm sulfur fuel, consult the engine manufacturer for service interval.

“RESOURCE CONSERVING” or “ENERGY CONSERVING”

These designations apply to oils intended for gasoline engines (cars, vans, and light trucks).

Widespread use of “Resource Conserving” or “Energy Conserving” oils may result in an overall savings of fuel in the vehicle fleet as a whole.

“Multiple Performance Requirements” levels

It is possible for oils designed for diesel engine service to also meet gasoline engine service. For these oils the designation is “C” category first followed by the “S” category. “C” category oils have been formulated primarily for diesel engines and may not provide all of the performance requirements consistent with vehicle manufacturers’ recommendations for gasoline-fueled engines.

Grease Consistency Classifications

So far, the products discussed have been fluids, but what about greases? In some lubricant applications, it is impossible to contain a fluid lubricant. For these applications, greases are used.

A simple description of grease is a semi-solid lubricant composed of base fluid, additives and a thickener. The thickener in grease is added in most cases to help keep the lubricant in place on applications where a fluid lubricant would run off and only provide lubrication for a very short time.

Because greases are not a fluid, their resistance to flow is generally called consistency instead of viscosity. Greases are sold by consistency grade.

Grease consistency is measured using the cone penetration test.

The National Lubricating Grease Institute (NLGI) created a set of ranges that have become the standard by which most greases are produced, marketed and sold. These ranges characterise the flow properties of greases.

Home Page | Products | About AMSOIL | Oil Basics | Buy Wholesale | FAQs | Contact Us | General Site Map